An Integrated MES, for any manufacturing business, can provide a whole range of benefits, both in the short term and the long term.

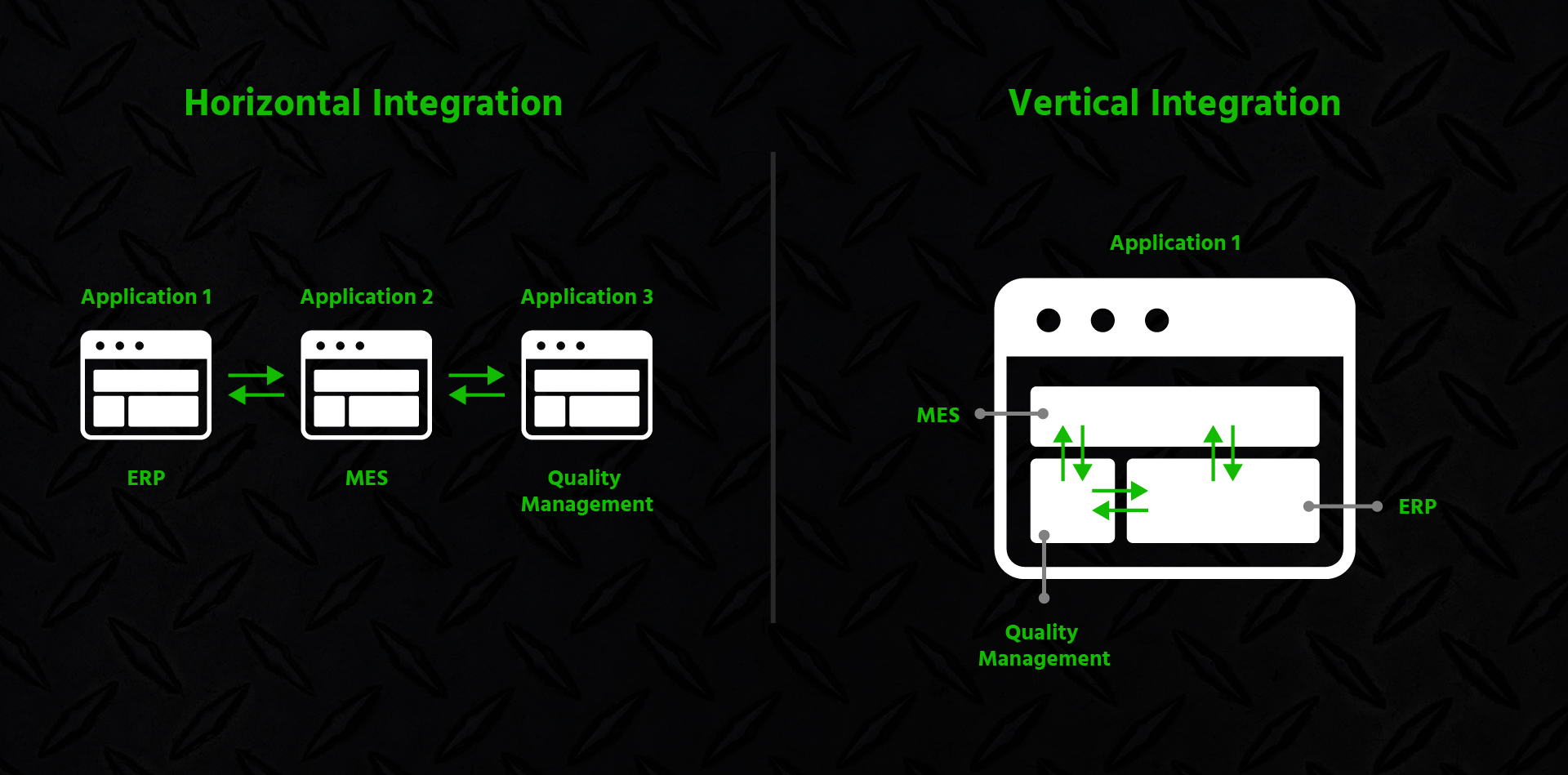

It makes the leap from having separate applications all being configured to talk to each other, to having one integrated platform where all the modules are synchronised in real-time.

In this post we’ll detail what an MES is, how it differs from an ERP and how your manufacturing business can benefit from having an integrated MES.

What is an MES?

MES stands for Manufacturing Execution System and is responsible for managing, monitoring and recording the transformation from raw materials to finished goods (production), within your manufacturing business.

What’s the difference between MES and ERP

The easiest way to differentiate between an MES and an ERP (Enterprise Resource Planning), is to say that an ERP is responsible for managing your business processes, whereas the MES is responsible for managing your production processes.

ERP Software will generally look after everything that happens either side of the production process within a manufacturing business.

From invoicing and HR to customer service and managing deliveries, the ERP is what allows your various business departments to share data and talk to each other.

However there is often a bit of a black hole in the overall business workflow due to the ERP and MES being in completely separate systems.

This black hole appears between the points of an order moving into production, and the product being dispatched to the customer.

This black hole is where an MES system fits.

It’s very common for ERP solutions to integrate with an MES in order to fulfil the manufacturing requirement of your business.

However this means you then have two different systems talking to each other (horizontal integration) and this can present problems and shortcomings further down the line.

Within DELMIAWORKS ,the MES and ERP elements of the application are seamless through one, vertically integrated solution.

Having a single application with all the modules built in, and communicating in real-time can provide a range of benefits to your manufacturing operation.

What are the benefits of an Integrated MES?

Increase Overall Equipment Effectiveness (OEE)

Within an effective MES, and particularly within DELMIAWORKS, the information that the system can draw on can help you improve scheduling of future jobs.

In DELMIAWORKS you can review the Standard Cycle Time against the Actual Cycle Time, which helps you to understand where jobs may finish early or late, and you can view this in real-time.

Over time you are able to track the trends of these cycles and it can work both ways.

You can see jobs that are always finishing late and can then use this information to more accurately plot your scheduling of jobs.

Or you can see jobs that always finish early, which can allow you to free up capacity and produce more items in the same time frame that was set in the Standard Cycle Time.

With just a few clicks of a button, the scheduling system knows all of this information and so when the planner is putting in a plan, or manipulating an existing one, this data is available right at their finger tips.

The benefit here is that you can increase the capacity of your manufacturing operation with no extra requirement for space or people, thus increasing the Overall Equipment Effectiveness (OEE).

Control the information that people can access

Another huge benefit to an integrated MES is the ability to control the information that people have access to.

Whether that’s ensuring they’ve got the most up to date information in front of them, or preventing people seeing information that they don’t need to access, document control can ensure that people have the right information at the right time.

This is a particularly useful feature if your business is utilising workflow instructions or assembly instructions for components within the production process.

As soon as a document is printed, it immediately becomes out of date and it’s no secret that processes and instructions change over time.

If you’re working from a set of printed instructions and someone makes an amendment to the original, your printed version is immediately out of date.

If you’re not working off the latest version of the document there’s always an increase in the number of things that can go wrong. With DELMIAWORKS, the document control is electronic.

There’s a workflow to approve each new document or amendment and it also includes a version history of the document so you always know which is the most up to date version.

It also operates a check-in, check-out system, which allows you to ensure that only the right people have access to the right documents at the right time.

This reduces the risk of your team having access to information and documents that are out of date, and preventing any number of headaches from appearing further down the line.

Prolong the useful life of your equipment and machinery

The MES provides you with Maintenance Repair Overhaul, sometimes called Preventative Maintenance.

The software knows how many cycles a machine has done. It could be dynamic based on the number of cycles, or it could be just that you need to change a filter every 30 days.

Send reminders, create maintenance orders, keep track of costs.

See how much your equipment and machinery is costing you every day/week/year.

It doesn’t just allow you to plan for maintenance and repairs of equipment within your production line either, it can track this for anything.

Does your heating or alarm system need servicing every year? Add it into the system and it will send you a reminder when that time comes.

Account for scheduled downtime when planning jobs

If you have machinery that requires servicing, or planned downtime throughout the year, you can enter the relevant dates into the system and it will show this information to the planner when they are planning jobs in.

If a client is asking you when a job can be completed, DELMIAWORKS will work it out for you taking into account the downtime window that is planned for that particular piece of equipment.

This helps remove situations where you may have promised a customer a specific date, but then the equipment needs a service which puts the entire production schedule behind plan.

Integrated MES in DELMIAWORKS Manufacturing ERP

The MES within DELMIAWORKS is vertically integrated and this makes the MES a core part of the functionality of the entire ERP system, allowing all modules to talk to each other and pass information and data around seamlessly.

It’s about having the right information and having control of that information, and this is something that DELMIAWORKS makes very easy for your business.

If you’re waiting to get information until a work order is finished, it’s too late to fix anything by that point.

If you have up to date, real-time information and control of the process, the schedule, the documents and foresight of maintenance windows, then you are much better set up for a smooth running and efficient production line.

This allows your people to get on with the work they are supposed to be doing, rather than firefighting issues in the production process because there’s a deadline to meet and a machine suddenly requires a service that nobody has been notified about.

If you take the pressure off your team to remember significant service dates, or remember which document is the most up to date one that people should be using, then it frees them up to do more of the things that make your business money.

If you’d like to know more about the way DELMIAWORKS integrated MES can improve the operations within your manufacturing business, our expert consultants would love to speak to you to help you make the right decision for your business.

Talk to our team today >

Posted by Rob on 29th March 2021.